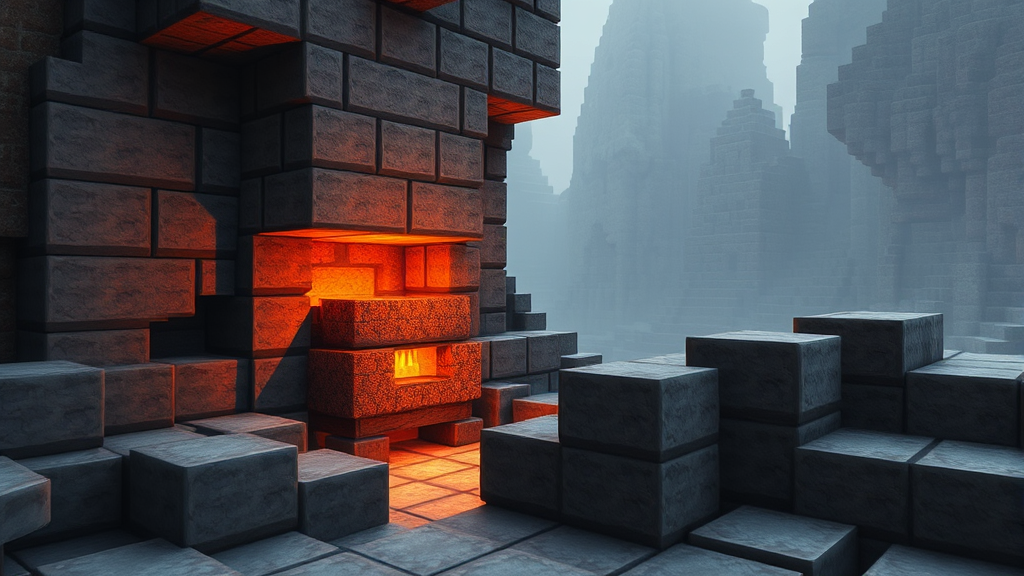

Master the Art of Crafting Smooth Stone in Minecraft

Smooth stone is one of Minecraft’s most versatile and aesthetically pleasing building materials, offering players a refined alternative to the rougher cobblestone texture. This polished block serves as both a functional crafting ingredient and an elegant decorative element that can transform any structure from basic to sophisticated. Whether you’re building a modern mansion, creating sleek pathways, or designing intricate redstone contraptions, mastering the art of smooth stone creation is essential for any serious Minecraft architect.

The process of creating smooth stone involves a two-step smelting procedure that transforms raw cobblestone into its refined counterpart. While the concept might seem straightforward, understanding the nuances of fuel efficiency, furnace management, and optimal production techniques can significantly enhance your building capabilities. This comprehensive guide will walk you through every aspect of smooth stone creation, from basic smelting to advanced automation systems.

Understanding Smooth Stone Basics

Smooth stone represents the refined evolution of cobblestone, achieved through a careful smelting process that removes the rough, irregular texture characteristic of its predecessor. Unlike regular stone blocks that can be mined directly with a silk touch pickaxe, smooth stone must be crafted through furnace smelting, making it a processed material that requires intentional effort and resource investment.

The transformation from cobblestone to smooth stone occurs in two distinct phases: first, cobblestone is smelted into regular stone, then the stone undergoes a second smelting cycle to achieve the smooth texture. This dual-process approach mirrors real-world stone refinement techniques, where raw materials undergo multiple stages of processing to achieve desired characteristics.

Smooth stone’s visual appeal lies in its uniform, seamless texture that creates clean lines and sophisticated surfaces. The block features a subtle gray coloration with minimal visible seams when placed adjacent to other smooth stone blocks, making it ideal for modern architectural designs and minimalist building styles.

Required Materials and Tools

Creating smooth stone requires a relatively simple set of materials, making it accessible to players at various stages of game progression. The primary components include cobblestone as the base material, a furnace for smelting, and fuel to power the smelting process. Each cobblestone block yields one smooth stone block, establishing a direct one-to-one conversion ratio.

Cobblestone serves as the foundation material and can be obtained through several methods. Mining stone blocks without a silk touch pickaxe automatically converts them to cobblestone, while stone generators provide renewable sources through lava and water interaction. Additionally, cobblestone can be found in various naturally generated structures throughout the Minecraft world.

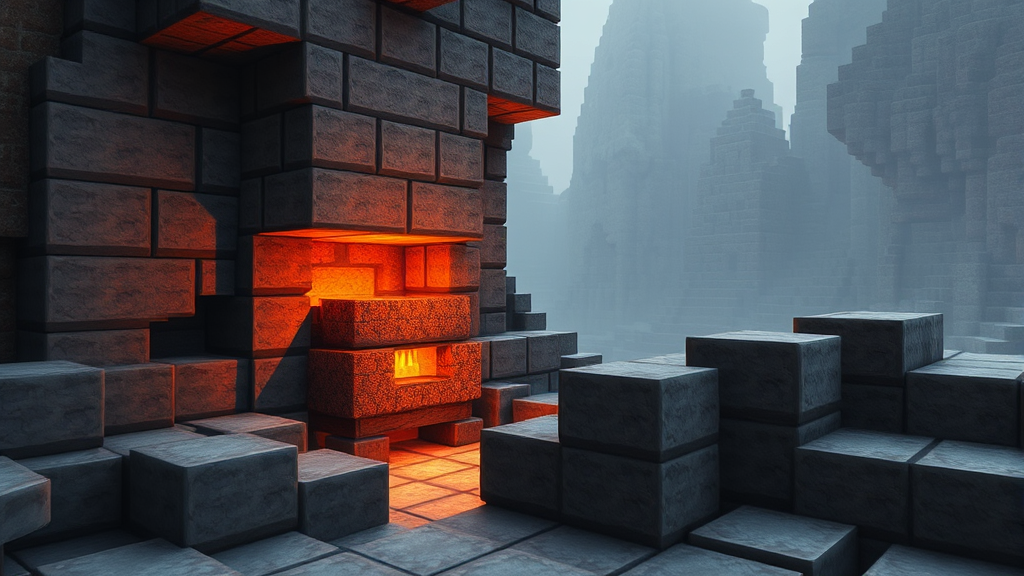

Furnace construction requires eight cobblestone blocks arranged in a hollow square pattern, creating the essential smelting apparatus. Multiple furnaces can significantly accelerate production rates, particularly when processing large quantities of smooth stone for extensive building projects. The furnace placement strategy can impact workflow efficiency, with centralized furnace rooms offering organized production environments.

Fuel selection plays a crucial role in smooth stone production efficiency. Coal remains the most common fuel choice, providing eight smelting operations per piece, while charcoal offers a renewable alternative through wood processing. More advanced fuel options include blaze rods, lava buckets, and various wood products, each offering different burn times and efficiency ratings.

Step-by-Step Smelting Process

The smooth stone creation process follows a methodical two-stage smelting procedure that transforms raw cobblestone into polished building material. Understanding each step ensures consistent results and optimal resource utilization throughout the production cycle.

Begin by placing cobblestone in the furnace’s top slot, with your chosen fuel in the bottom slot. The initial smelting process converts cobblestone into regular stone blocks, which serve as the intermediate material for smooth stone creation. This first stage typically requires standard smelting time, with progress indicated by the furnace’s flame animation and progress bar.

Once the cobblestone-to-stone conversion completes, remove the stone blocks from the furnace output slot and immediately place them back into the top input slot. Add additional fuel if necessary, then initiate the second smelting cycle. This crucial second stage transforms regular stone into smooth stone, completing the refinement process.

Timing coordination becomes essential when managing multiple furnaces simultaneously. Staggering the start times allows for continuous production flow, with stone blocks from early furnaces ready for second-stage processing as later furnaces complete their initial cycles. This approach maximizes efficiency and minimizes idle time between production phases.

Quality control throughout the process ensures consistent results. Monitor fuel levels to prevent incomplete smelting cycles, and organize inventory space to accommodate both intermediate stone blocks and final smooth stone products. Proper organization prevents material loss and streamlines the production workflow.

Fuel Efficiency and Resource Management

Optimizing fuel consumption directly impacts the sustainability and cost-effectiveness of smooth stone production. Different fuel types offer varying burn durations and smelting capacities, requiring strategic selection based on availability and production goals. Understanding these efficiency metrics enables informed resource allocation decisions.

Coal provides the most balanced fuel option for most players, offering eight smelting operations per piece with widespread availability through mining operations. Charcoal presents a renewable alternative created by smelting wood logs, making it ideal for players with limited coal access or those prioritizing sustainable resource management practices.

Advanced fuel options include lava buckets, which provide one hundred smelting operations per bucket, making them extremely efficient for large-scale production. However, lava bucket usage requires careful planning due to bucket retrieval mechanics and the need for reliable lava sources. Blaze rods offer twelve smelting operations each but require nether exploration and blaze farming capabilities.

Resource calculation becomes crucial for planning large building projects. Each smooth stone block requires two fuel units (one for each smelting stage), meaning efficient fuel management directly correlates with production capacity. Creating fuel reserves before beginning major smooth stone production prevents workflow interruptions and ensures project completion.

Much like maintaining clean equipment when learning how to clean stainless steel pans in real-world cooking, keeping your furnaces organized and well-fueled ensures optimal smooth stone production results.

Automation and Mass Production

Advanced players often seek automation solutions to streamline smooth stone production, particularly for large-scale building projects requiring hundreds or thousands of blocks. Redstone-powered systems can automate various aspects of the smelting process, from material input to output collection and storage organization.

Hopper-based automation systems provide the foundation for automated smooth stone production. Input hoppers can automatically feed cobblestone into furnaces, while output hoppers collect finished products and route them to storage systems. Fuel hoppers ensure continuous operation by maintaining furnace fuel levels without manual intervention.

Multi-stage automation requires careful timing coordination to manage the two-step smelting process. Intermediate storage systems temporarily hold stone blocks between smelting stages, while sorting mechanisms direct materials through appropriate processing channels. These systems can be expanded to include automatic cobblestone generation through stone generators.

Redstone timing circuits control the flow between production stages, ensuring stone blocks complete the first smelting cycle before advancing to smooth stone production. Clock circuits and comparator-based systems provide precise timing control, while observer blocks detect furnace state changes to trigger material movement.

Large-scale automation installations can incorporate multiple furnace arrays, parallel processing lines, and sophisticated storage systems. These industrial-scale operations require significant resource investment but provide enormous production capacity for mega-builds and server-wide construction projects.

Building Applications and Design Ideas

Smooth stone’s versatile aesthetic properties make it suitable for numerous architectural styles and building applications. Its clean, uniform texture complements both modern minimalist designs and classical architectural elements, providing builders with exceptional creative flexibility across diverse construction projects.

Modern architectural applications showcase smooth stone’s sleek appearance through clean lines, geometric forms, and minimalist design principles. Contemporary homes, office buildings, and public structures benefit from smooth stone’s sophisticated appearance, particularly when combined with glass, metal accents, and strategic lighting elements.

Classical and historical building styles also incorporate smooth stone effectively, serving as refined alternatives to rougher stone materials. Medieval castles, Renaissance palaces, and neoclassical structures gain elegance through smooth stone applications in walls, floors, columns, and decorative elements.

Functional applications extend beyond pure aesthetics to include practical construction needs. Smooth stone floors provide durable, attractive surfaces for high-traffic areas, while smooth stone walls offer clean backdrops for artwork, item frames, and decorative displays. The material’s neutral coloration complements various color schemes and design themes.

Creative combinations with other materials expand smooth stone’s design potential. Pairing smooth stone with wood creates warm, inviting atmospheres, while combinations with concrete and glass emphasize modern, industrial aesthetics. Understanding these material relationships enables sophisticated architectural compositions.

Just as precision is important when learning how to cut plexiglass for real construction projects, careful planning and material selection enhance smooth stone building applications in Minecraft.

Troubleshooting Common Issues

Smooth stone production can encounter various challenges that impede efficiency and quality. Understanding common issues and their solutions ensures consistent results and prevents resource waste during the smelting process. Proper troubleshooting techniques maintain production momentum and optimize resource utilization.

Incomplete smelting cycles represent the most frequent production issue, typically caused by insufficient fuel supplies or premature furnace interaction. Always ensure adequate fuel levels before beginning smelting operations, and avoid removing items before the smelting process completes. Progress bars provide visual indicators of smelting status, preventing premature interruptions.

Inventory management challenges often arise during large-scale production, particularly when processing multiple furnace outputs simultaneously. Organize inventory space before beginning production, and consider using chest storage systems to accommodate large quantities of materials. Proper organization prevents item loss and streamlines workflow management.

Fuel efficiency problems can significantly impact production costs and sustainability. Calculate fuel requirements before beginning major projects, and maintain adequate reserves to prevent production interruptions. Consider fuel type selection based on availability and burn efficiency to optimize resource allocation.

Automation system malfunctions require systematic troubleshooting approaches. Check hopper connections, redstone signal integrity, and timing circuit functionality when automated systems fail to operate correctly. Regular maintenance and testing prevent system failures during critical production periods.

Material quality issues, such as accidentally smelting stone into regular stone instead of smooth stone, can be prevented through careful attention to smelting stages. Always verify that stone blocks undergo the second smelting cycle to achieve smooth stone texture. Double-checking materials prevents confusion and ensures desired results.

Frequently Asked Questions

Can I obtain smooth stone through mining with a silk touch pickaxe?

No, smooth stone cannot be obtained through mining, even with a silk touch enchanted pickaxe. Smooth stone must be created through the two-stage furnace smelting process, starting with cobblestone, converting it to stone, then smelting the stone again to create smooth stone. This crafted nature makes smooth stone a processed material that requires intentional production.

What’s the difference between smooth stone and regular stone blocks?

Regular stone blocks have a slightly rougher texture with more visible grain patterns, while smooth stone features a completely uniform, polished appearance with minimal texture variation. Regular stone can be obtained by mining stone blocks with a silk touch pickaxe or by smelting cobblestone once. Smooth stone requires the additional second smelting step to achieve its characteristic smooth finish.

How much fuel do I need to make a stack of smooth stone?

Creating 64 smooth stone blocks requires 128 fuel units total, since each block needs two smelting cycles. Using coal as fuel, you would need 16 coal pieces (128 ÷ 8 operations per coal). With charcoal, you’d need the same amount. Using more efficient fuels like lava buckets would require approximately 1.3 buckets for a full stack of smooth stone.

Can I use smooth stone in crafting recipes?

Yes, smooth stone is used in several crafting recipes, most notably for creating smooth stone slabs, which require three smooth stone blocks arranged horizontally in a crafting table. Smooth stone slabs are popular for creating refined flooring, roofing, and decorative elements. Smooth stone can also be used in place of regular stone in most building applications where a cleaner appearance is desired.

Is there a faster way to produce large quantities of smooth stone?

The fastest method for large-scale smooth stone production involves setting up multiple furnaces with automated hopper systems. Create arrays of 10-20 furnaces with input hoppers feeding cobblestone and fuel, plus output hoppers collecting finished products. Implement a two-stage system where stone from the first furnace array automatically feeds into a second array for the final smoothing process. This automation can produce hundreds of smooth stone blocks per hour.

What happens if I accidentally smelt smooth stone again?

Smelting smooth stone in a furnace doesn’t change it further – it remains as smooth stone. The game doesn’t have a third refinement stage beyond smooth stone, so additional smelting simply consumes fuel without altering the block’s properties. This makes smooth stone the final form in the cobblestone refinement chain.

Can I convert smooth stone back to cobblestone or regular stone?

No, the smooth stone creation process is irreversible through normal gameplay mechanics. Once cobblestone has been refined into smooth stone, it cannot be converted back to its previous forms. This one-way transformation means players should carefully plan their smooth stone production quantities to match their building needs. Consider keeping some regular stone blocks for recipes that specifically require non-smooth stone materials.